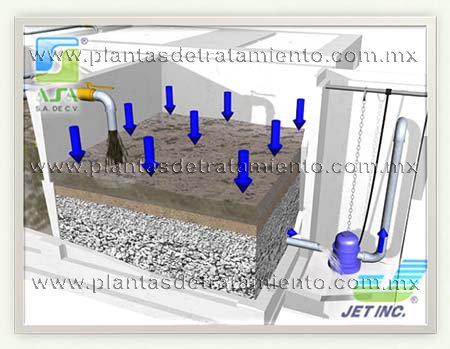

DESIGN AND PROCESS UNITS

ASA/JET plants are completely modular, ideal in solving wastewater problems for Condos, Schools, Hotels, Hospitals, Factories, Buildings, Supermarkets, Service Stations, Airports, Industrial Parks, etc.

According to the volume and degree of contamination of waste water, our engineers come to make a modular design package, to ensure plant effluent fulfills of environmental law, and with an add-on flexibility for a future easily, quickly and economically expansion.

The six process units of a ASA / JET Wastewater treatment Plant integrate with a JET electro mechanical equipment.

THE PROCESSING UNITS THAT MAKE UP AN ASA / JET WASTEWATER TREATMENT PLANT ARE:

PROCESS UNITS

1 – Pretreatment

1A- Sand trap channel

1B- Sidehill screen

2 – Equalizing and Pump Station

3 – Biological Reactor

4 – Clarifier

5 – Chlorination

6 – Digester

7 – Drying Beds

THE ELECTRO MECHANICAL EQUIPMENT IS COMPOSED OF:

A – Control Panel

B – Aeration Unit

C – Pipes, Valves and Connections

THE FLEXIBLE AND MODULAR DESIGN ALLOWS YOU TO EASILY EXPAND FUTURE

CAPACITY OF THE WASTEWATER TREATMENT PLANT.

1.PRETREATMENT

The waste water is fed by gravity to the pretreatment unit where large objects and materials that can not be treated biologically are removed, such as plastic, glass, metals etc.

1A. SAND TRAP CHANNEL

Sand Trap Channels are constructed in prefabricated reinforced concrete JET Modules and are equipped with Stainless or Carbon Steel screens and gates to remove solids such as sand, stones, etc.

1B.SIDEHILL SCREEN

The Sidehill screen removes solids larger than 1.0 mm, before the wastewater enter the treatment plant.

The drum screen is suitable for BOD fine particles removal. Used when the organic load is very high and separates particles larger than 200 microns. Paper fiber is also removed.

2.EQUALIZING AND PUMP STATION

This processing unit aerates, homogenized and regulates the flow variations in the input of contaminated water to the wastewater treatment plant. This process is aerobic and uses pumping and regulation integrated systems.

The control panel regulates the alternation in the operation of the duplex pumps installed. A return line with a valve is installed in the head of the pumps to regulate the flow to the wastewater treatment plant, according to flow design.

Previously regulated wastewater enters the reactor where the Sewage Treatment starts

Bacteria present in the activated sludge or biomass, feed and breed, transforming contaminated water into a clear liquid that generates no odors.

ASA / JET Wastewater Treatment Plants use process of activated sludge in extended aeration mode, whose effectiveness has been proven for many years.

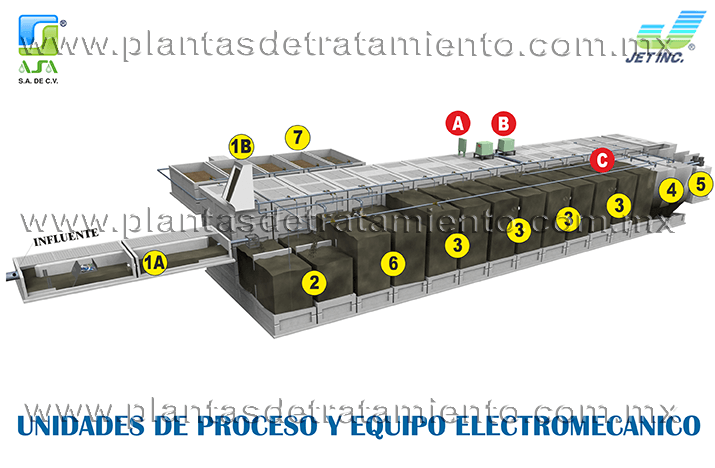

In the clarifier, the water from the bioreactor remains completely still and most of the particles that are in suspension settle down.

A Jet Skimmer removes and returns the remaining floating particles.

A JET adjustable aluminum effluent weir, with a “V” section that retains floating particles, continuously output clear water from the wastewater treatment plant.

This clear, odorless and highly decontaminated water is the only effluent that leaves ASA/JET Wastewater Treatment Plants, to be reused or returned to the environment.

5.CHLORINATION

The effluent from the clarifier unit flows to the disinfection unit which consists of a JET tablet chlorinator, simple in design, durable and efficient in its operation. It works by gravity flow, and uses easy to handle JET disinfectant tablets that dissolve slowly eliminating the harmful, pathogenic agents to man´s health.

This effluent can be spilled into lakes, lagoons, or stored in a Treated Water Cistern to be used for watering green areas, fountains, decorative waterfalls, toilets, and for re-use in industrial processes such as in cooling towers.

The most important water treatment goal is the protection of the environment. Further economic and fiscal benefits are obtained as a reduction in rates of drinking water supplied, full deduction of investment in the taxable year, etc.

6. DIGESTER

Part of the activated sludge that settles in the Clarification unit is sent to the Digester processing unit for complete stabilization. Microorganisms in activated sludge remain for 25 days thus achieving stabilization of sludge, which does not generate any odors and insects.

Here the bacteria do not get food so initially consume the remaining contaminants and then the endogenous or cannibalism phase begins where they are self-consumed.